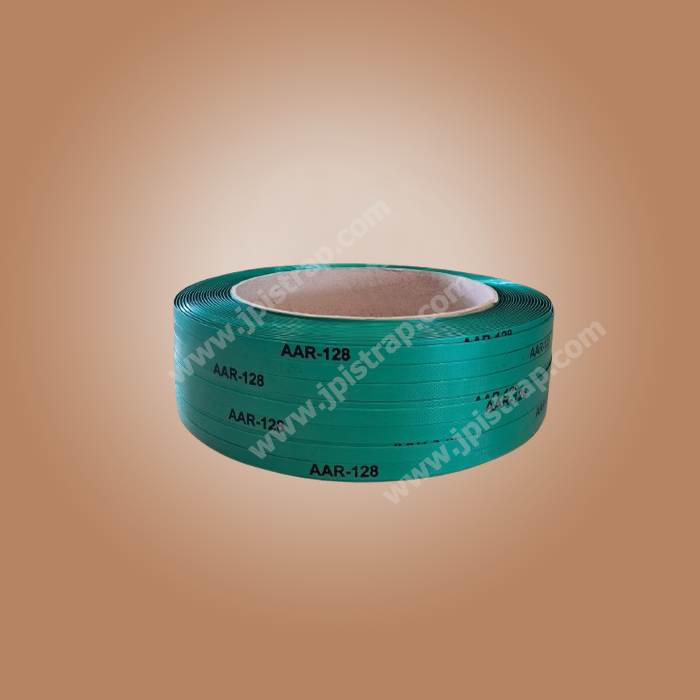

Pet Strapping Features:

Pet Strap Roll has a reputation of reliable and strong performance and it has a range of distinct characteristics that makes it to be an ideal entertainment of loading in industries. These are some of the main features of PET Strap Roll:

- High Tensile Strength: PET Strap Roll possesses high tensile strength which implies that it will withstand large objects without breaking. This has made it quite adequate when securing the heavy loads like pallets, bundles and large packages.

- Elasticity: The PET Strap Roll is more elastic unlike other materials. This enables it to have a slight stretch under torque, which renders it more versatile regarding the variations of loads and creates extra safety in the transportation process.

- Lightweight: The PET strap rolls are considerably lighter as compared to steel or other metal strapping material. This makes them simpler to manipulate, apply and transport, aiding in cutting down costs of labor and lessening the weight added on the whole package.

- Corrosion Resistance: PET strap rolls have moisture, rust, and corrosion resistance which cannot be said about steel strapping. This is a key attribute that adds more value to their use in industries where products are left under the weather conditions or stored in a humid area.

- Smooth Surface: PET strap roll has a smooth and even surface. This eliminates the possibility of products getting damaged and also injuries that may occur when handling sharp edges; this may be a concern with steel straps.

- UV and Weather Resistance: PET strap rolls are UV resistant, thus, it does not break or decline when left under sunlight over a long period of time. This renders them usable in the open air sitting, as well as transport. Moreover, they are resistant to temperature changes, and are strong in varying weather.

- Recyclability: PET strap rolls are produced using recyclable plastic which make the packaging offering more sustainable and environmentally-friendly. This is the very characteristic that is key to companies that want to minimize their WHERE-impacts.

- Flexible and Easy to Handle: PET strap roll is both easy to handle and adjust as it can be applied easily when securing your load. It may be suited to either manual or automatic strapping systems, which provide convenience and efficiency as regards strapping.

- Cost-Effective: Since it is less costly as compared to steel straps, PET strap rolls can be used economically by facilitating the business that is required to have the large loads bound with straps.

- High Shock Absorption: PET strap rolls are elastic and thus considered to have good shock absorbers. This aspect can ensure that the products are not affected by any shocks or vibrations that could be used when shipping products, thus minimizing the chances of breakage.

- Consistent Quality: PET strap rolls are serviced to a tight specification that means they are strong and durable. Such premium level will minimize the chances of a strap breakage and enhance load stability as a whole.

- Non-Conductive: PET strap rolls are not conductive hence are safe to use in electrical apparatus or in places where minting conductivity is an issue.

- Wide Range of Sizes and Strengths: The selection of PET strap rolls has different widths and thickness as well as strengths thus giving business variety in choosing the best type of strap rolls to suit their unique packaging requirements.

- Low Maintenance: PET strap rolls do not rust or degrade thus they need little care maintaining and this makes them easier to use as time goes by than their counterparts which are made up of metals.

These traits turn PET strap rolls into a universal and secure effective cover option of numerous industries like logistics services, warehouses, shipping, and manufacturing. When it comes to a desire to find something strong, durable, or convenient to use, PET straps can be the right choice.

PET Strap Roll Specifications:

The specifications of PET strapping can vary depending on the manufacturer and the specific needs of the application. However, there are general guidelines and standards that help define PET strapping’s characteristics. Below are the key specifications commonly associated with PET strapping:

| Specification | Typical Range |

| Material | Polyethylene Terephthalate (PET) |

| Width | 12 mm to 32mm |

| Thickness | 0.6 mm to 1.3 mm |

| Tensile Strength | 150 kg to 1,200 kg |

| Elongation at Break | 10% to 20% |

| Breaking Load | 200 kg to 2,000 kg |

| Coil Size | 5 kg to 500 kg (varies by application) |

| Color | Clear, Black, Blue, Green, etc. |

| UV Resistance | Available with UV stabilizers |

| Surface Finish | Smooth or Embossed |

| Temperature Resistance | -40°C to 80°C |

| Recyclability | Yes (recyclable) |

| Core Size | 200 mm to 406 mm |

These specifications give a general idea of the capabilities and variations of PET strap rolls. However, depending on your specific needs (like load weight, application environment, or machine type), you might find customized specifications that are more suited to your requirements.