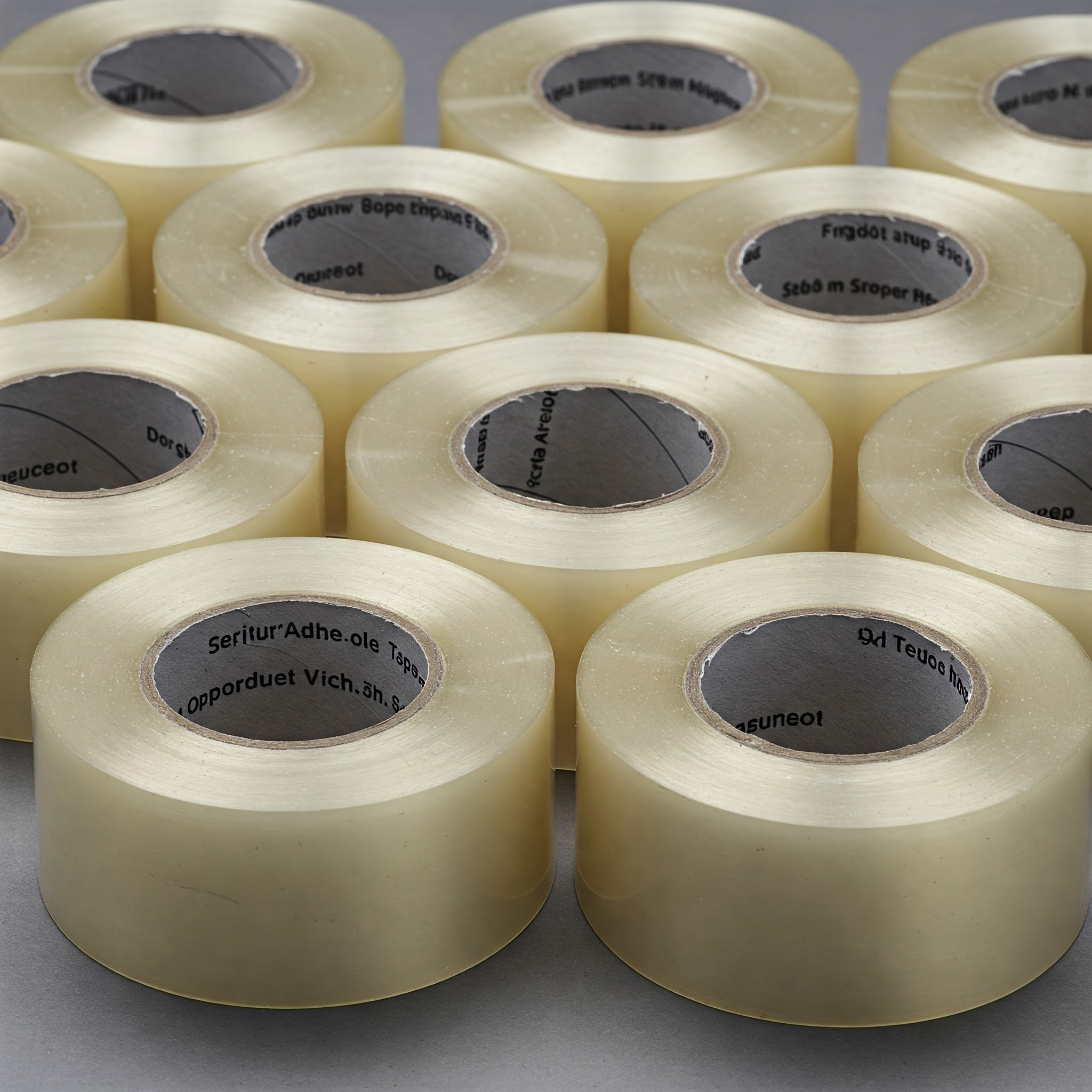

BOPP Tape / Cello Tape / Self-Adhesive Tapes

Self Adhesive Tape manufacturers

Self adhesive tape manufacturers play a crucial role in today’s fast-paced industrial, packaging, and consumer markets by offering high-performance bonding solutions. These tapes, commonly known as pressure-sensitive tapes, are designed to stick to surfaces without the need for heat or water. Top manufacturers produce a wide range of self-adhesive tapes such as BOPP packaging tapes, masking tapes, double-sided tapes, electrical insulation tapes, duct tapes, and speciality industrial tapes tailored to meet the needs of diverse applications.

Leading self adhesive tape manufacturers combine advanced coating technology with premium-grade adhesives and films to deliver tapes with excellent bonding strength, long-lasting adhesion, and resistance to moisture, chemicals, and temperature variations. These manufacturers cater to various industries, including packaging, electronics, automotive, construction, medical, and retail. Whether it’s sealing cartons, insulating wires, mounting components, or providing surface protection, self adhesive tapes offer a clean, efficient, and reliable solution.

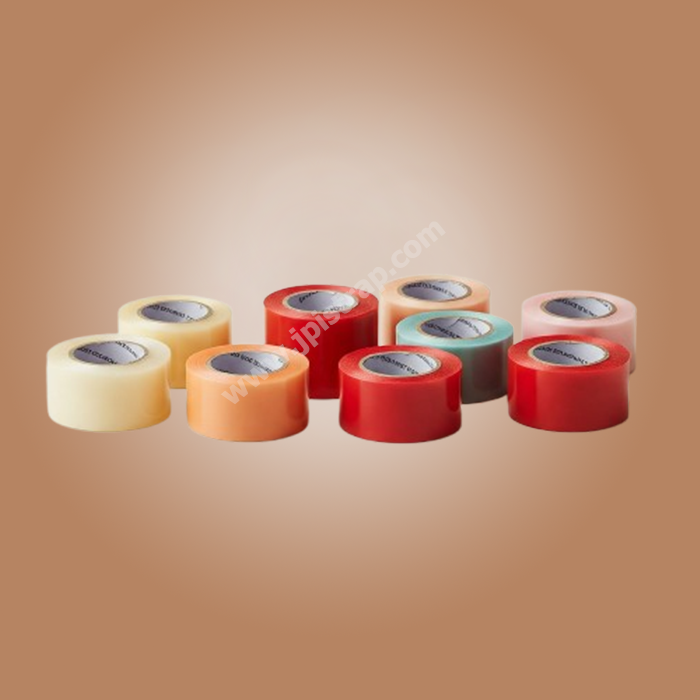

In India, self adhesive tape manufacturing has evolved significantly with companies adopting automated machinery, eco-friendly adhesives, and high-speed slitting and rewinding lines. Many manufacturers also comply with international standards like ISO, RoHS, and REACH, ensuring consistent quality and global export potential. Customization is another key offering, with options in tape width, length, thickness, color, printing, and adhesive type to suit specific application needs.

With increasing demand for tamper-proof and branded packaging solutions, self adhesive tape manufacturers now offer printed BOPP tapes featuring company logos, product details, or warning messages, adding both security and marketing value. These tapes are available in both solvent-based and water-based adhesives, depending on the required tack and holding power.

Choosing a trusted self adhesive tape manufacturer ensures not just product reliability but also timely delivery, technical support, and cost-effective solutions. Whether you are a packaging company, distributor, or end user, sourcing from an established manufacturer helps you streamline your operations with high-quality adhesive products. As industries continue to grow and packaging becomes more specialized, self adhesive tape manufacturers remain integral to enhancing product safety, efficiency, and branding.

Stretch Film Features:

- Strong Adhesion:Provides a firm grip on various surfaces like plastic, metal, glass, and cardboard.

- High Tensile Strength:Offers durability and resistance to tearing, making it ideal for packaging and sealing.

- Easy Application:Simple to apply by hand or with a dispenser; no heat or water activation required.

- Variety of Adhesives:Available in Acrylic, Rubber, and Silicone-based adhesives for different applications.

- Multiple Backing Materials:Comes in BOPP, PVC, Paper, Foam, Cloth, and Aluminum Foil backings.

- Weather & Moisture Resistance:Many variants are resistant to humidity, temperature changes, and water.

- Available in Different Sizes & Thicknesses:Ranges from 12mm to 72mm width and 35 to 150 microns thickness.

- High Transparency & Printability:Clear and colored options available; can be customized with branding and logos.

- Noise-Free & Low-Noise Options:Certain tapes unwind silently, suitable for quiet environments.

- Heat & UV Resistance: Some specialized tapes can withstand high temperatures and UV exposure for outdoor use.

- Multipurpose Usage: Used in packaging, electrical insulation, masking, mounting, and industrial applications.

- Eco-Friendly Options: Some tapes are biodegradable or made with recyclable materials.

Specifications of Self-Adhesive Tapes

|

Base Material |

|

|

Adhesive Type |

|

|

Tape Thickness |

|

|

Width Options |

|

|

Length Options |

|

|

Color & Transparency |

|

|

Temperature Resistance |

|

|

Tensile Strength |

|

|

Peel Strength & Adhesion |

|

|

Specialized Features |

|