PP Strapping Roll Manufacturer

Strapping Features:

-

High Speed and Efficiency

Fully automatic machines are designed for high-speed operation, significantly increasing throughput and reducing packaging time.

-

Automated Operation

These machines handle the entire strapping process automatically, from feeding the strapping material to tensioning, sealing, and cutting, with minimal human intervention.

Fully automatic strapping machines are used where speed and flexibility in packaging varieties are required and paralleled with maintenance of efficiency and productivity. The main features are the following ones:

- Consistent Tension and Sealing: They provide consistent tension of straps and reliable seal leading to uniform strapped packages.

- Programmable Setting: Most automatic fully automatic strapping machines have programmable settings that can enable the user to program in strapping parameters that best fit their different packaging requirement.

- Integration Capabilities: They could also be attached to the already established production lines which could easily work with the conveyor belts and other packages machinery to present an entirely computerized packaging system.

- Flexibility: Can be used with large and small packages, with different types of packages, supports different materials and widths of strapping.

- High Accuracy: Sophisticated measures of control and sensors will give high accuracy in the placement and secure strapping to lessen the chances of damage to the package.

- Durable Construction: Comprised of high quality materials and parts to be utilized in the continuous heavy-duty use found on industrial applications.

- Minimal Downtime: Its design offers fast changes on its strapping rolls and maintenance, and overall it has minimal downtime due to its ease of maintenance and ability to change strapping rolls quickly.

- Safety Features: To maintain safety, many safety considerations have been incorporated where they have emergency stop buttons, automatic shutdown in case of a malfunction and have protective covers to make sure the operator is not hurt.

- Energy Efficiency: Some of them are energy-efficient, such as use of automatic standby when it is idle to save power.

- User interfaces: These interfaces are friendly and usually have touch screen capability and controls that are easy to configure, monitor and use.

- Remote Monitoring and Diagnostics: Some more sophisticated models possess the functionality of remote monitoring and diagnostics, which makes it possible to track the performance in real time and fix it.

- Low Operating Costs: At higher initial cost, fully automatic strapping machines have the capability to bring down the operating cost in the long run due to higher efficiency, less labour cost and low wastage of material.

The characteristics of fully automatic strapping machines refer these products to the business with a large scale packaging requirement as these products guarantee industry-level efficiency and performance in the packaging requirement.

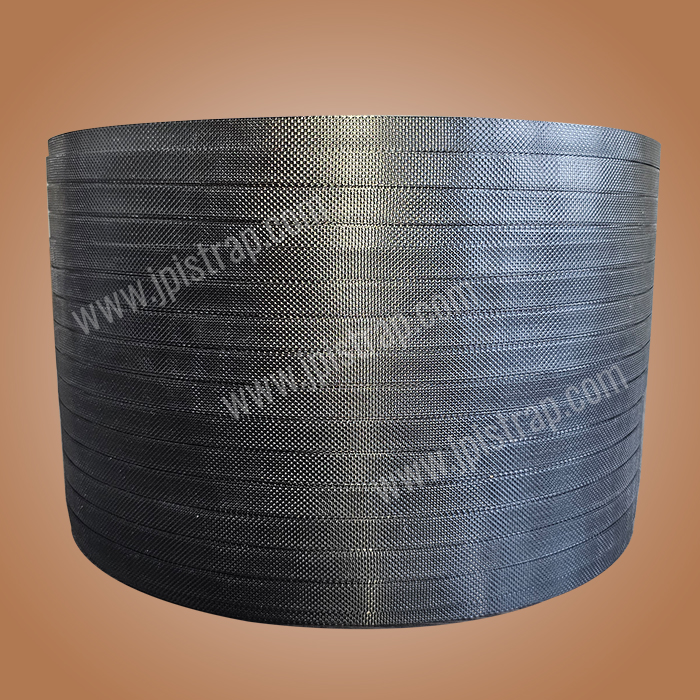

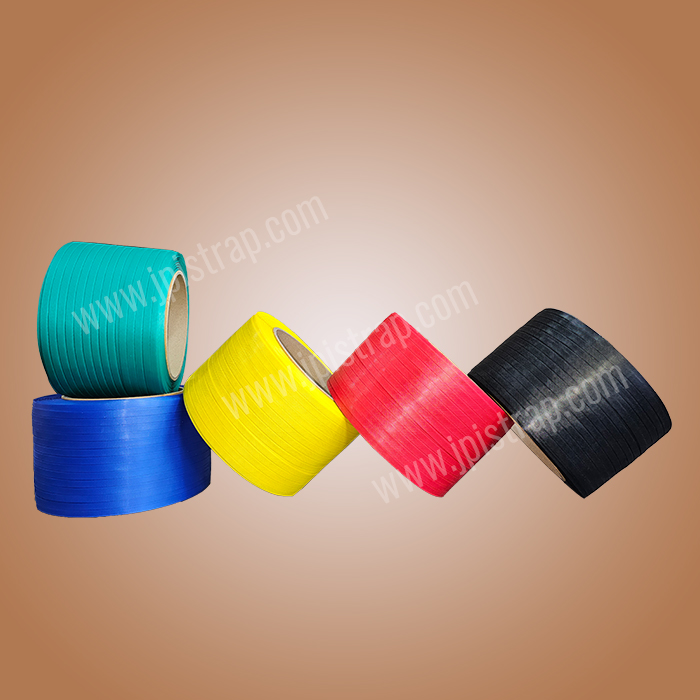

Strapping Specifications:

Fully automatic polypropylene (PP) strapping rolls are designed for use in automatic strapping machines. Here are some typical specifications you might find for these strapping rolls:

| Material | Polypropylene (PP) |

| Dimensions – Width | Common widths are 5mm,8mm, 9mm,11 mm, 12mm, and 15mm. |

| Thickness | Typically ranges from 0.5mm to 1.0mm. |

| Length | Varies based on the roll size, commonly between 2000 meters to 7000 meters per roll. |

| Tensile Strength | Typically ranges from 200 N to 500 N, depending on the width and thickness of the strap. |

| Core Diameter | Common core diameters are 200mm, 280mm, and 406mm. |

| Color | Available in various colors including black, white, blue, and custom colors as per requirements. |

| Breaking Strength | Generally ranges from 100 kg to 300 kg, depending on the strap specifications. |

| Surface Finish | Can be embossed or smooth, depending on application needs. |

| Elongation | Typically around 20% to 25% at break. |

| Compliance | Should comply with relevant industrial standards and regulations such as ISO, ASTM, or DIN standards. |

| Packaging | Usually packed in paper tubes, with protective wrapping to prevent damage during transport. |

| Winding | Core length: 190 MM |

These specifications can vary depending on the manufacturer and the specific application requirements. It’s always a good idea to consult with the supplier or manufacturer for the exact specifications tailored to your needs.

| Code (Plain / Printed) | Width (-0.2 to -0.6mm) | Thick (0.00 to 0.08 mm) | Length Average /Me terage +5% | Average Net Weight (Kgs)+ 100gm | Average Strength (+ 5% kgs) |

| JPI860 | 8 | 0.60 | 2000 | 5.800 | 65 |

| JPI870 | 8 | 0.70 | 2000 | 6.000 | 80 |

| JPI960 | 9 | 0.60 | 2000 | 6.000 | 80 |

| JPI970 | 9 | 0.70 | 2000 | 7.000 | 85 |

| JPI1160 | 11 | 0.60 | 2000 | 7.000 | 90 |

| JPI1170 | 11 | 0.70 | 2000 | 8.000 | 110 |

| JPI1255 | 12 | 0.55 | 2500 | 10.00 | 120 |

| JPI1255 | 12 | 0.55 | 3000 | 12.00 | 120 |

| JPI1260 | 12 | 0.60 | 2000 | 8.000 | 110 |

| JPI1270 | 12 | 0.70 | 2000 | 9.000 | 120 |

| JPI1280 | 12 | 0.80 | 2000 | 10.00 | 120 |

| JPI1560 | 15 | 0.60 | 1500 | 9.000 | 130 |

| JPI1570 | 15 | 0.70 | 1000 | 7.000 | 150 |

| JPI1580 | 15 | 0.80 | 1000 | 8.000 | 160 |

| JPI1590 | 15 | 0.90 | 1000 | 9.000 | 170 |

| JPI1860 | 18 | 0.60 | 1000 | 7.000 | 170 |

| JPI1870 | 18 | 0.70 | 1000 | 8.000 | 175 |

| JPI1880 | 18 | 0.80 | 1000 | 9.000 | 180 |

PP Strapping Roll Price