Strapping Features:

Semi-automatic polypropylene (PP) strapping machines have various features providing improvement of the strapping process. Main features are the following:

- Ease of Use: Such machines are easy to use, and training on its use is minimal. Pallet packages are easier to strap using the semi- automatic process.

- Efficiency: They make the strapping process faster and more efficient than manual strapping, which has proved to be ideal in medium-volume strapping.

- Consistent Tension: The strapping is provided with even pressure through the machines each time achieving a secure and consistent packaging.

- Adjustable Tension: The majority of semi-automatic strapping machines have variable tension on most cases so that they can adapt to various package sizes and applications.

- Versatility: It fits both large and small package quantities and addresses packaging flexibility to varying conditions.

- Portability: Most semi-automatic types of strapping machine are of compact size and are quite portable enabling one to easily transfer it within a working area.

- Automatic Feed: Automatic Feed:Here the strapping is fed into the machine automatically thus cutting the number of people involved and minimizing the time of doing so.

- Energy Efficiency: They will be energy efficient in most cases with most of the machines having inbuilt auto power off capability when not used to conserve energy.

- Durability: The materials used to construct it are durable and able to endure frequent use in industries and business premises.

- Cost-Effective: Provide a trade off between manual and fully automatic strapping solutions, offering a cost effective solution to the business community that does not require high-speed strapping.

- Safety Features: Most of them come with guard features to guard the operator against any mishap that may arise in the strapping process.

- Minimal Maintenance: It is created in such a way that a minimum of maintenance is required, the parts are easy to work on and access to both the fixing and replacing such parts

Such characteristics make semi-automatic PP strapping machines a viable option to businesses that require to up-scale their packaging process without having to invest in Complete-Automatic units.

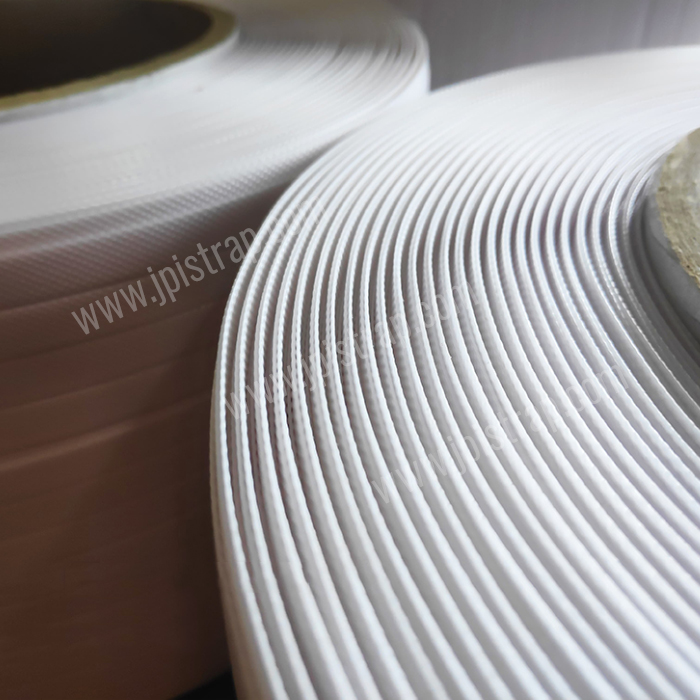

Strapping Specifications:

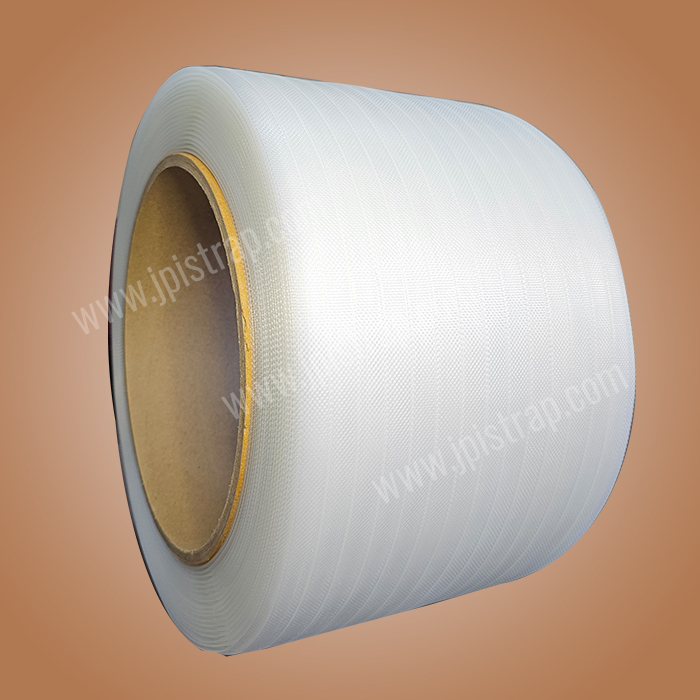

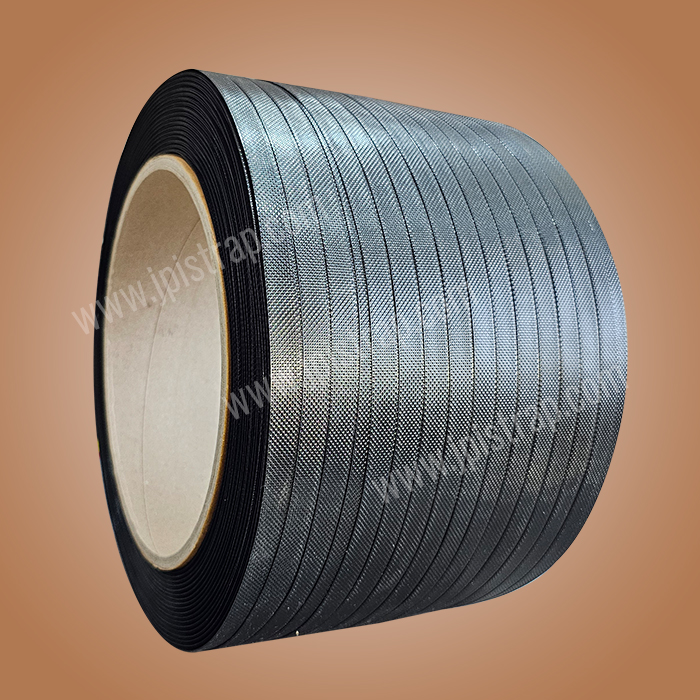

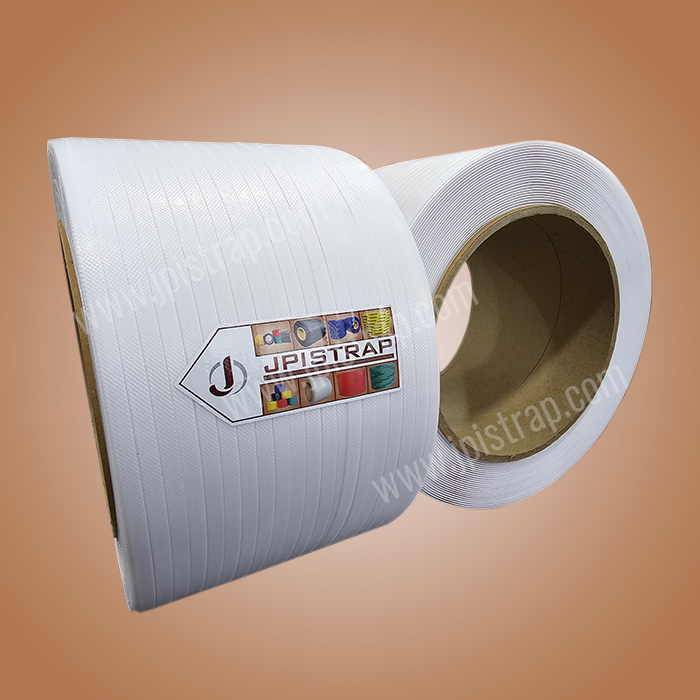

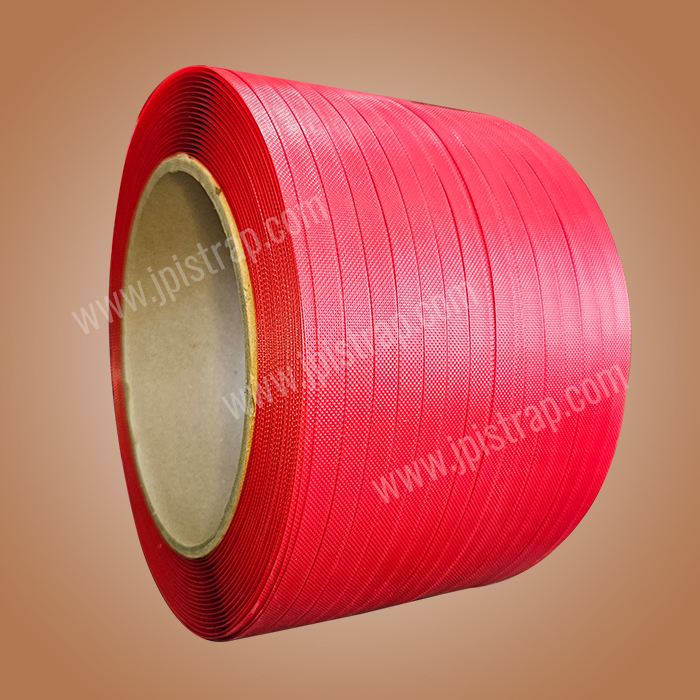

Semi-automatic polypropylene (PP) strapping rolls are designed for use in semi-automatic strapping machines. Here are the typical specifications:

| Material | Polypropylene (PP) |

| Dimensions – Width | Common widths are 5mm, 9mm, 12mm, and 15mm. |

| Thickness | Typically ranges from 0.5mm to 1.0mm. |

| Length | Varies based on the roll size, commonly between 2000 meters to 3000 meters per roll. |

| Tensile Strength | Typically ranges from 150 N to 400 N, depending on the width and thickness of the strap. |

| Core Diameter | Common core diameters are 200mm, 280mm, and 406mm. |

| Color | Available in various colors including black, white, blue, and custom colors as per requirements. |

| Breaking Strength | Generally ranges from 70 kg to 200 kg, depending on the strap specifications. |

| Surface Finish | Can be embossed or smooth, depending on application needs. |

| Elongation | Typically around 15% to 25% at break. |

| Compliance | Should comply with relevant industrial standards and regulations such as ISO, ASTM, or DIN standards. |

| Packaging | Usually packed in paper tubes, with protective wrapping to prevent damage during transport. |

| Winding | Core length: 190 MM & 165 MM |

These specifications can vary depending on the manufacturer and the specific application requirements. It’s advisable to consult with the supplier or manufacturer for the exact specifications tailored to your needs.

| Code (Plain / Printed) | Width (-0.2 to -0.6mm) | Thick (0.00 to 0.08 mm) | Length Average /Me terage +5% | Average Net Weight (Kgs)+ 100gm | Average Strength (+ 5% kgs) |

| JPI850 | 8 | 0.50 | 3000 | 7.000 | 65 |

| JPI950 | 9 | 0.50 | 3000 | 7.500 | 70 |

| JPI960 | 9 | 0.60 | 2000 | 6.000 | 75 |

| JPI1150 | 11 | 0.50 | 2000 | 6.300 | 75 |

| JPI1160 | 11 | 0.60 | 2000 | 7.000 | 85 |

| JPI1170 | 11 | 0.70 | 2000 | 8.000 | 110 |

| JPI1250 | 12 | 0.50 | 2000 | 7.000 | 85 |

| JPI1260 | 12 | 0.60 | 2000 | 8.000 | 110 |

| JPI1550 | 15 | 0.50 | 1500 | 7.500 | 110 |

| JPI1560 | 15 | 0.60 | 1000 | 6.000 | 125 |

| JPI1570 | 15 | 0.70 | 1000 | 7.000 | 140 |

| JPI1580 | 15 | 0.80 | 1000 | 8.000 | 160 |

| JPI1850 | 18 | 0.50 | 1000 | 7.000 | 150 |

| JPI1860 | 18 | 0.60 | 1000 | 8.000 | 165 |

| JPI1870 | 18 | 0.70 | 1000 | 9.000 | 175 |