Being one of the best cord strap manufacturers in India, we excel in providing heavy-duty, strong and cost-effective strapping requirements with high strength. The cord straps (or polyester cord straps) are high-tenacity polyester fiber-based products broadly used to strap heavy loads in transit. These straps are strong and flexible, and even hostile weather conditions do not fully affect them; hence, they are an ideal alternative to the tough steel strapping. Be it an industrial packaging, cargo, or container lashing, our cord straps are safe and reliable. We also come in the list of the best manufacturers of composite straps in India, where we deal with high-quality strapping which utilize co-extruded fibers of polyester bound in a polymer layer. The composite straps stretch together the good features of the cord straps and the additional feature that is abrasion resistance and excellent shock absorbency. They are portable, convenient and less hazardous to the handlers than the traditional metal strapping. Our strapping products and solutions in the form of composite strappings can be used in securing pallets, timber, steel coils, machinery, and bulky shipments. We fulfil the domestic and international market with state-of-the-art manufacturing units, high-quality inspection and fast delivery. Our straps have passed the test of the global standards and can be used in different widths and in different strengths so as to vary with various packaging requirements. Being one of the most reliable cord and composite strap manufacturers in India, we are prone to offering reliable, environmentally friendly and affordable packaging material that can fulfil the needs of the contemporary logistics and transportation industry.

Cord Strap Features:

High Strength & Durability

Flexibility & Shock Absorption

Lightweight & Safe to Use

Rust & Corrosion Resistant

Weather & Chemical Resistance

Easy to Handle & Apply

Reusability & Cost-Effectiveness

Specifications of Cord Strap / Composite Strap

Types of Cord Straps / Composite Strap

- Composite Cord Strapping: Coated with a polymer for extra durability, resists moisture and abrasions.

- Woven Cord Strapping: High flexibility and strength, ideal for heavy loads

- Bonded Cord Strapping: Made of glued polyester fibers, used for medium-duty applications.

Common Sizes & Strengths

Width (mm) | Width (inch) | Break Strength (kg) | Break Strength (lbs) |

13 mm | ½” | 300 – 450 | 660 – 990 |

16 mm | ⅝” | 450 – 600 | 990 – 1320 |

19 mm | ¾” | 600 – 1100 | 1320 – 2425 |

25 mm | 1″ | 1100 – 1500 | 2425 – 3300 |

32 mm | 1¼” | 1500 – 2000+ | 3300 – 4400+ |

Elongation & Tension Retention

- Typically has 5% – 15% elongation, which helps absorb shock.

- Maintains tension over time, unlike steel or plastic strapping.

Temperature & Weather Resistance

- Can withstand extreme temperatures (-40°C to 80°C)

- Resistant to UV rays, moisture, and most chemicals

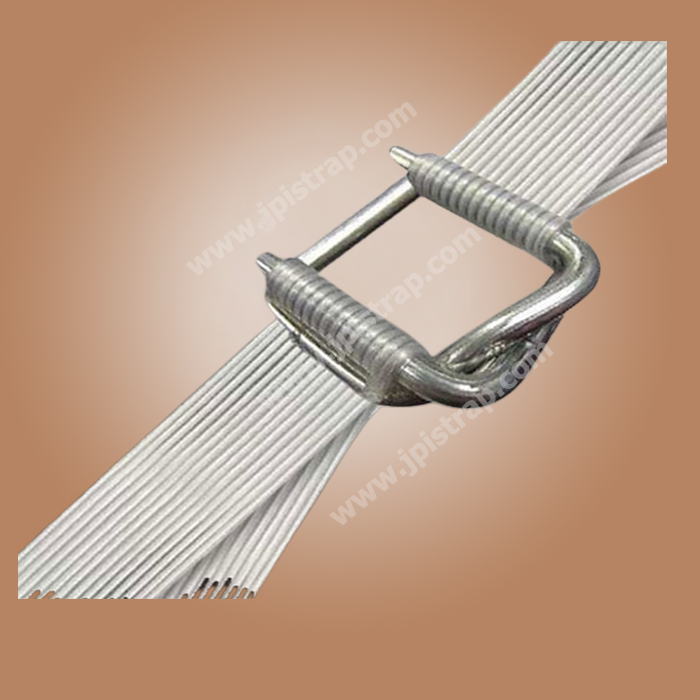

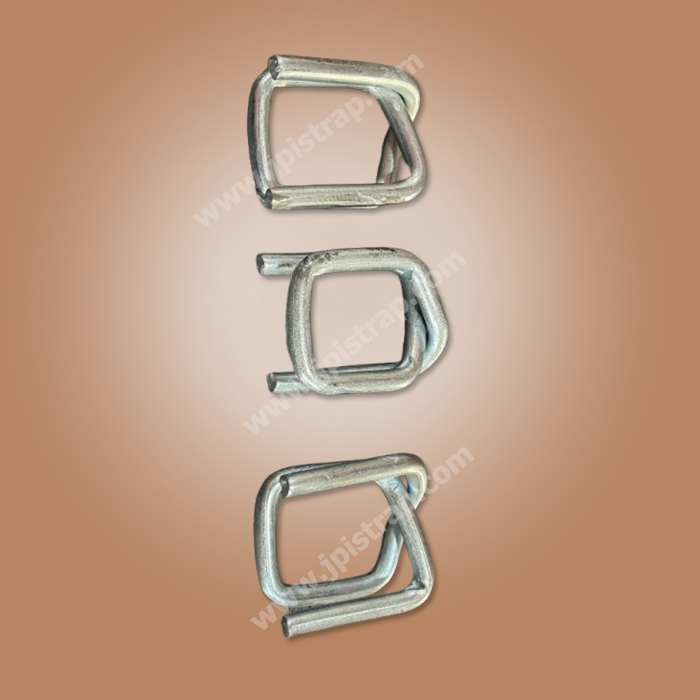

Joint & Buckle Types

- Phosphated/Bright Wire Buckles: For high-tension locking.

- Galvanized Buckles: Corrosion-resistant for outdoor use.

- Plastic Buckles: For light-duty applications.