Strapping Features:

Polypropylene (PP) strapping is easily and readily applied manually and it provides a flexible solution to the packaging application. These are their main features:

- Simplicity: Strapping using the manual method is easy to master and it does not involve any sophisticated equipment thereby making it user friendly in multiple environments.

- Portability: Because it does not require big equipment, manual strapping tools can be used at various and diverse locations, easily.

- Cost-Effective: The cost of investment is small as no special machines are needed so it can be considered a cost-effective method by small companies or when there is low business..

- Versatility: Can fit most sizes and shapes of packages in a flexible manner to meet different strapping requirements.

- Minimal Maintenance: Manual strapping devices are non-complicated and are also reasonably durable and can serve a long period with less maintenance as compared to automatic types.

- No Power Requirement: Does not require power, electricity or batteries so that it can be used where it is unlikely to access to power.

- Control and Precision: The strapping tension and placement is done by an operator and is fully controllable with precision where needed.

- Lightweight Tools: Manual strapping hand tools tend to be lightweight, which eliminates the fatigue of the operator and are easy to manipulate.

- Safety: Manual tools may be provided with additional safety to prevent the injury; e.g. tension control, protective handles.

- Adaptability: Due to its flexibility and portability, it may be utilized in any environment such as warehouses, shipping centres and outdoor places.

- Low Noise: Manual strapping equipment produces a very low level of noise as compared to an automatic strapping machine and thus is applicable in a quieter work setting.

- Customizable: Depending on application requirements, a variety of different manual tools (tensioners, sealers, and cutters) can be chosen.

These characteristics render manual PP strapping a viable option with small scale operations, low budget companies and scenarios where flexibility and portability is the main factor.

Strapping Specifications:

Manual polypropylene (PP) strapping rolls are to be used in combination with manual strapping and buckles. The following are the common specifications:

| Material | Polypropylene (PP) |

| Dimensions – Width | Common widths are 5mm, 9mm, 12mm, and 15mm. |

| Thickness | Typically ranges from 0.5mm to 1.0mm. |

| Length | Varies based on the roll size, commonly between 1000 meters to 2000 meters per roll. |

| Tensile Strength | Typically ranges from 150 N to 350 N, depending on the width and thickness of the strap. |

| Core Diameter | Common core diameter is76mm. |

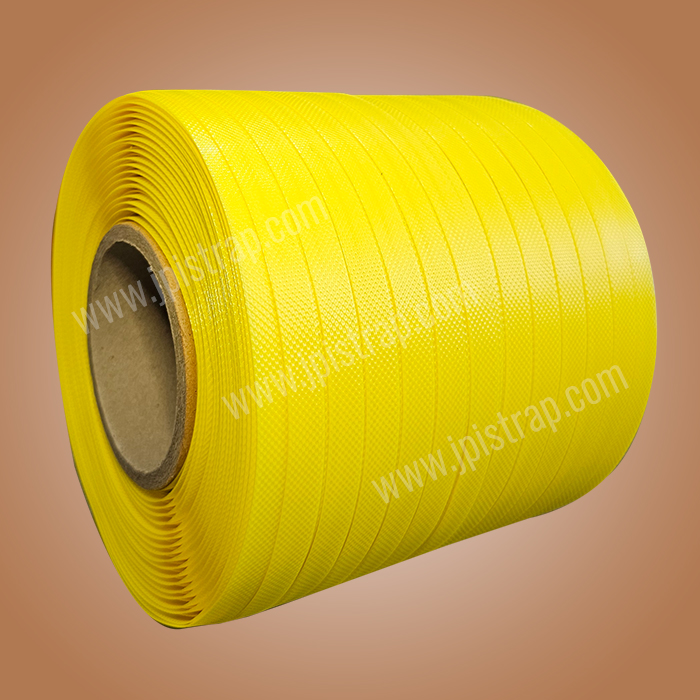

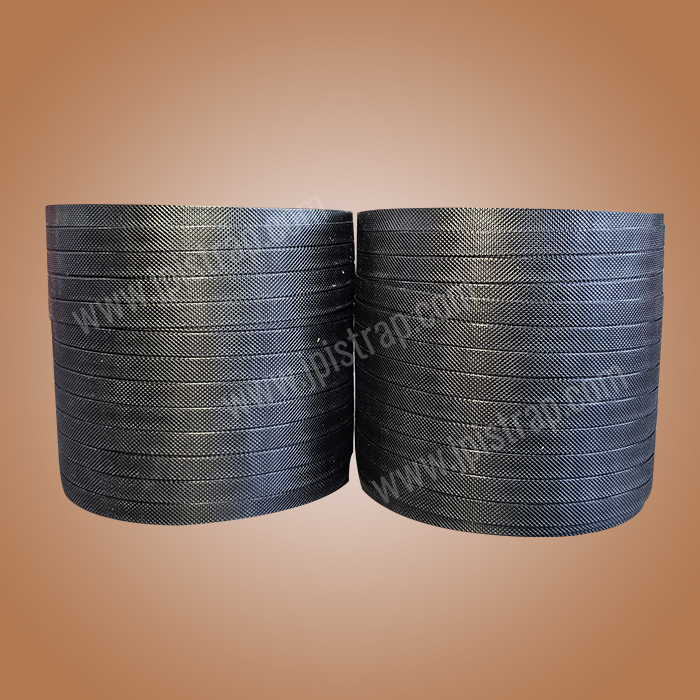

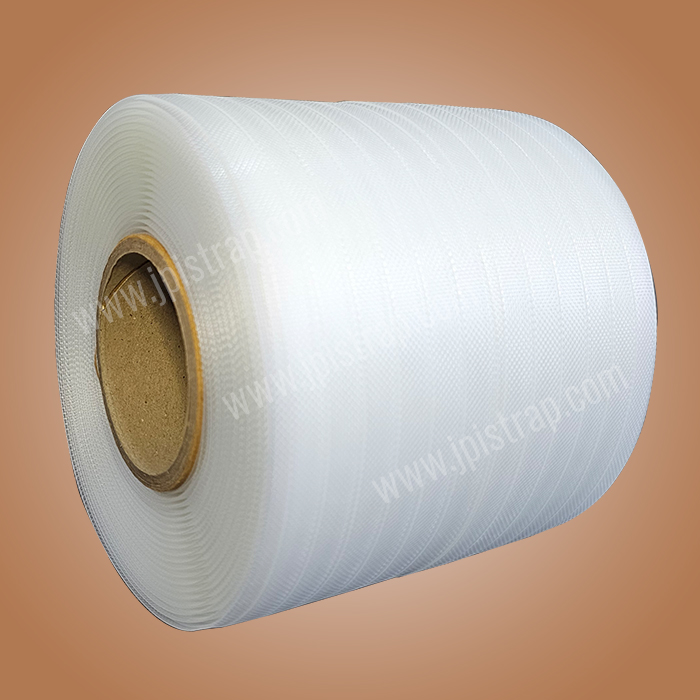

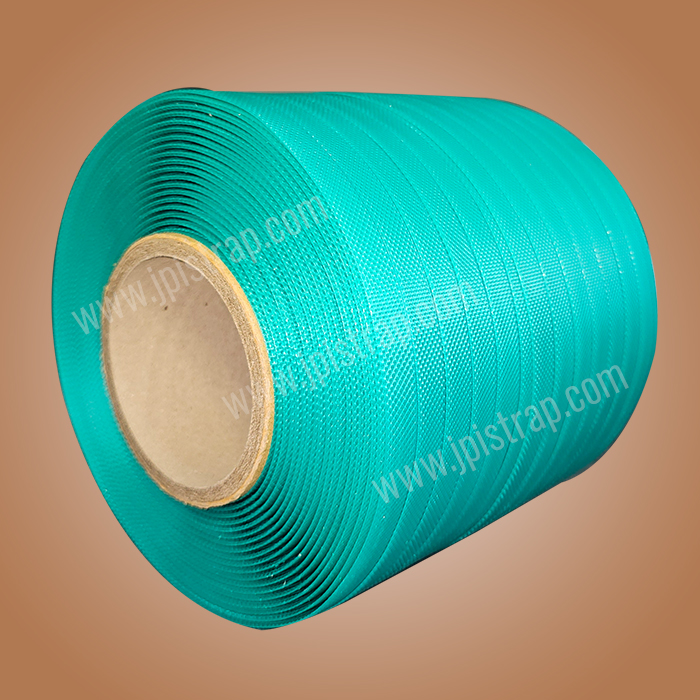

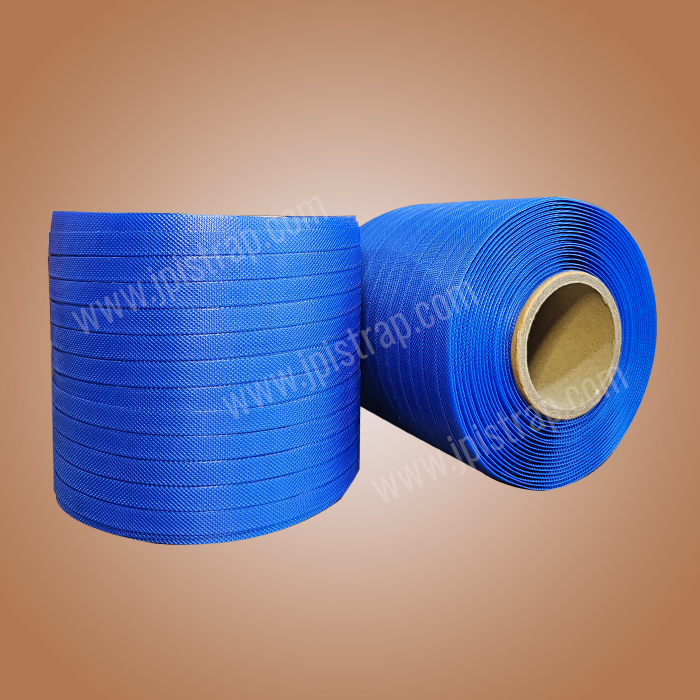

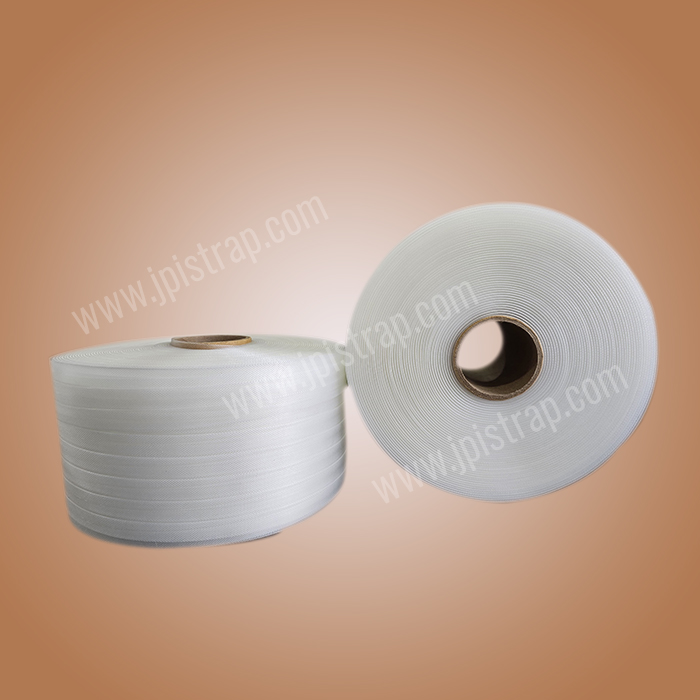

| Color | Available in various colors including black, white, blue, yellow, and custom colors as per requirements. |

| Breaking Strength | Generally ranges from 50 kg. To 200 kg., depending on the strap specifications. |

| Surface Finish | Can be embossed or smooth, depending on application needs. |

| Elongation | Typically around 10% to 25% at break. |

| Compliance | Should comply with relevant industrial standards and regulations such as ISO, ASTM, or DIN standards. |

| Packaging | Usually packed in paper tubes, with protective wrapping to prevent damage during transport. |

| Winding | Core length: 165 MM |

These specifications can vary depending on the manufacturer and the specific application requirements. It’s advisable to consult with the supplier or manufacturer for the exact specifications tailored to your needs.

| Code (Plain / Printed) | Width (-0.2 to -0.6mm) | Thick (0.00 to 0.08 mm) | Length Average /Me terage +5% | Average Net Weight (Kgs)+ 100gm | Average Strength (+ 5% kgs) |

| JPI850 | 8 | 0.50 | 3000 | 7.000 | 65 |

| JPI950 | 9 | 0.50 | 3000 | 7.500 | 70 |

| JPI960 | 9 | 0.60 | 2000 | 6.000 | 75 |

| JPI1150 | 11 | 0.50 | 2000 | 6.300 | 75 |

| JPI1160 | 11 | 0.60 | 2000 | 7.000 | 85 |

| JPI1170 | 11 | 0.70 | 2000 | 8.000 | 110 |

| JPI1250 | 12 | 0.50 | 2000 | 7.000 | 85 |

| JPI1260 | 12 | 0.60 | 2000 | 8.000 | 110 |

| JPI1550 | 15 | 0.50 | 1500 | 7.500 | 110 |

| JPI1560 | 15 | 0.60 | 1000 | 6.000 | 125 |

| JPI1570 | 15 | 0.70 | 1000 | 7.000 | 140 |

| JPI1580 | 15 | 0.80 | 1000 | 8.000 | 160 |

| JPI1850 | 18 | 0.50 | 1000 | 7.000 | 150 |

| JPI1860 | 18 | 0.60 | 1000 | 8.000 | 165 |

| JPI1870 | 18 | 0.70 | 1000 | 9.000 | 175 |