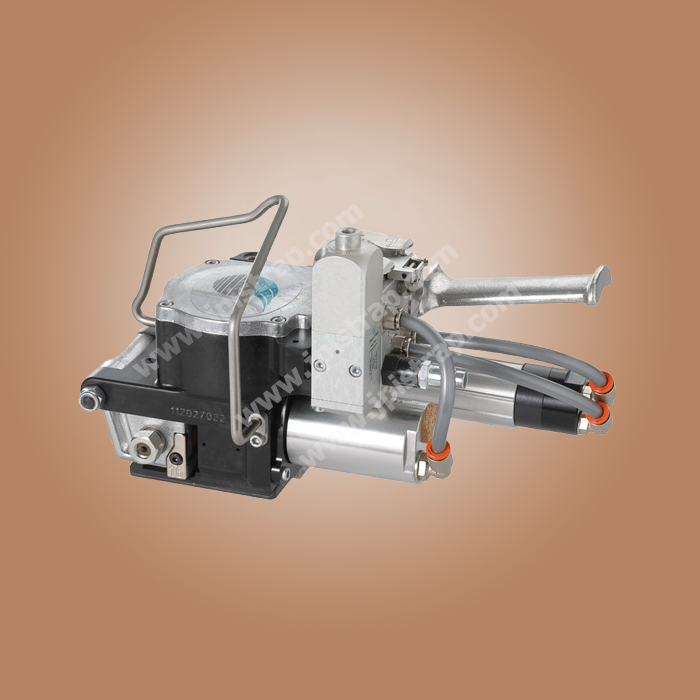

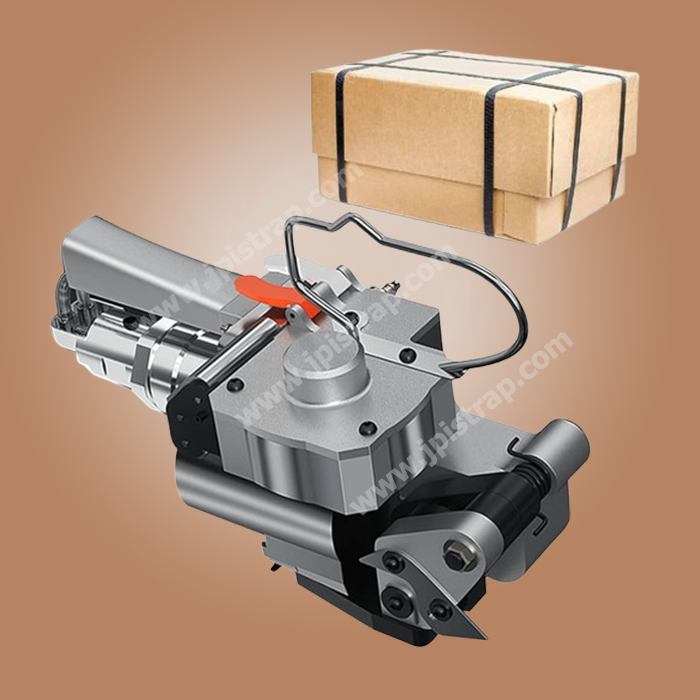

A Pneumatic Strapping Tool Manufacturer offers high quality packaging solutions that enable companies to fasten heavy-weight loads in a quick and accurate manner. Compressed air based pneumatic strapping products provide high levels of tension and consistent sealing of PET and PP straps. They are common in steel manufacturing, bricks, textiles, logistics, shipping and construction industries where the products have to be packed closely and securely to store or transport. Compared to manual strapping systems, pneumatic tools are more efficient and less fatiguing to the operator, so they are more favored by heavy and bulky packaging systems.

Pneumatic strapping tool manufacturers aim to design equipment that is durable, lightweight, and easy to handle, providing a consistent output. Most of the tools are equipped with the adjustable tension option, friction welding or heat sealing, and friendly designs that allow users to be comfortable with them. They can accommodate high-tension demands and that is why packages are in perfect condition during long distance delivery. Pneumatic strapping tools manufacturers employ superior materials and technology to make their products durable, strong and with minimal maintenance.

When selecting a trusted manufacturer of pneumatic strapping tools, businesses will get tools that can improve their productivity and cut costs related to packaging. Most manufacturers also offer after sales, spare parts and servicing of their products to maintain continuous operations. Available in a variety of strap thicknesses and strap widths, these tools can be tailored to fit a particular industry requirement. Any business that needs speed, safety, and efficiency in their packaging processes should invest in pneumatic strapping tools. Reputable manufacturers are known to guarantee the highest quality in their products, which improves load security overall.

Pneumatic Strapping Tool manufacturer

Features of Pneumatic Strapping Tool for Polyester (PET) & Polypropylene (PP) Strapping

High Tensioning Force

Automatic Friction Weld Sealing

Fast & Efficient Operation

Compatible with Different Strap Sizes

Lightweight & Ergonomic Design

Durable & Robust Construction

Adjustable Tension & Sealing Time

Requires Compressed Air

Integrated Cutter for Easy Strap Removal

Safe & User-Friendly

Specifications of Pneumatic Strapping Tool for Polyester (PET) & Polypropylene (PP) Strapping

Feature | Specification |

Strap Type | Polyester (PET) & Polypropylene (PP) |

Strap Width | 12mm – 19mm (Some models support up to 25mm) |

Strap Thickness | 0.5mm – 1.5mm |

Tension Force | 2000N – 3500N (Varies by model) |

Sealing Type | Friction Weld Sealing (No metal seals required) |

Sealing Strength | 75% – 85% of the strap breaking strength |

Tension Adjustment | Adjustable via regulator |

Air Pressure Required | 0.5 – 0.8 MPa (72 – 116 psi) |

Tool Weight | 3.5 – 6.0 kg |

Construction Material | High-quality aluminum alloy |

Strapping Speed | 3 – 5 seconds per cycle |

Operation Mode | Semi-automatic (requires air compressor) |