Stretch Film Features:

- High Elasticity & Stretchability:Can stretch up to 300% of its original length, providing excellent load stability.

- Self-Adhesive Cling:Clings to itself without glue or tape, ensuring a secure wrap without residue.

- Tear & Puncture Resistance:Designed to withstand sharp edges and rough handling during transit.

- Moisture & Dust Protection:Acts as a protective barrier against dirt, dust, and water.

- Transparency & Clarity:Allows easy identification of packaged products without unwrapping.

- Available in Different Thicknesses (Microns):Ranges from 8 to 35 microns, suitable for different load types.

- Lightweight & Cost-Effective:Reduces packaging costs compared to strapping or shrink wrapping.

- Safety Features: Equipped with multiple safety mechanisms, including emergency stop buttons, automatic shutdown in case of malfunctions, and protective covers to ensure operator safety.

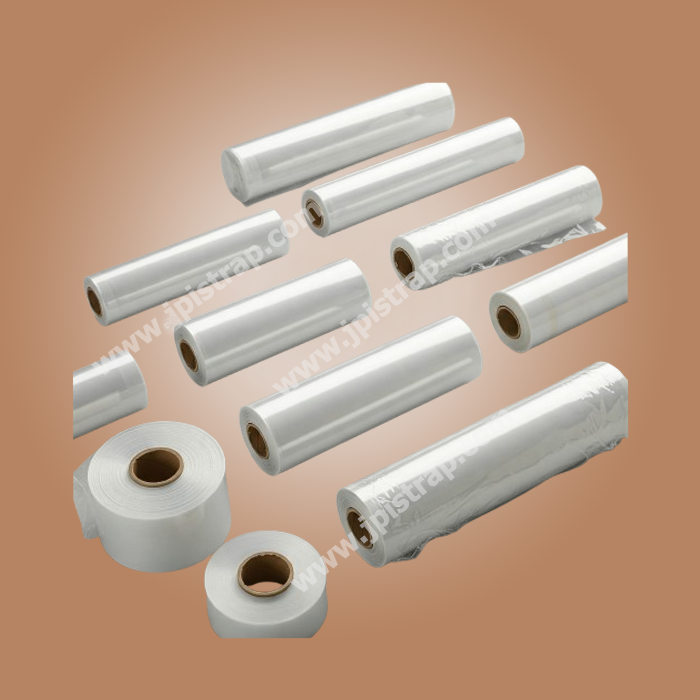

- Types Available:Hand stretch film, machine stretch film, blown stretch film, and cast stretch film for different applications.

- Eco-Friendly Options:Some variants are recyclable and biodegradable.

- Multi-Layer Construction:Enhances durability, stretch ratio, and load retention capabilities.

Stretch Film manufacturer in gujarat

Gujarat has become a major centre in providing Industrial packaging solutions which are of high quality, and among them are Stretch Film manufacturer in Gujarat who are very much important in providing the rising demand for secure, cost-effective and efficient Industrial packaging. Stretch wrap, or stretch film, is a very elastic plastic film that is stretched to envelop protection of products and pallets during storage and transportation. Famous manufacturers of Gujarat are manufacturers of all types of stretch films, such as machine-grade, hand-grade, coloured, and UV resistant as well as pre-stretched films that can be used in different industries.

With access to a high-technology manufacturing facility, skilled manpower and quality raw material, the best stretch film manufacturer in Gujarat makes sure that the performance of the film is high, with better puncture resistance and cling characteristics as well as uniform thickness throughout. These movies are best to use on the lining of cartons, packaging products and balancing of pallet loads. Whether it is in the FMCG, logistics, pharmaceuticals, agriculture, or electronics industry, Gujarat-based stretch wrap manufacturers provide the best quality stretch wrap solution that increases efficiency and efficiency in packaging with minimal material wastage.

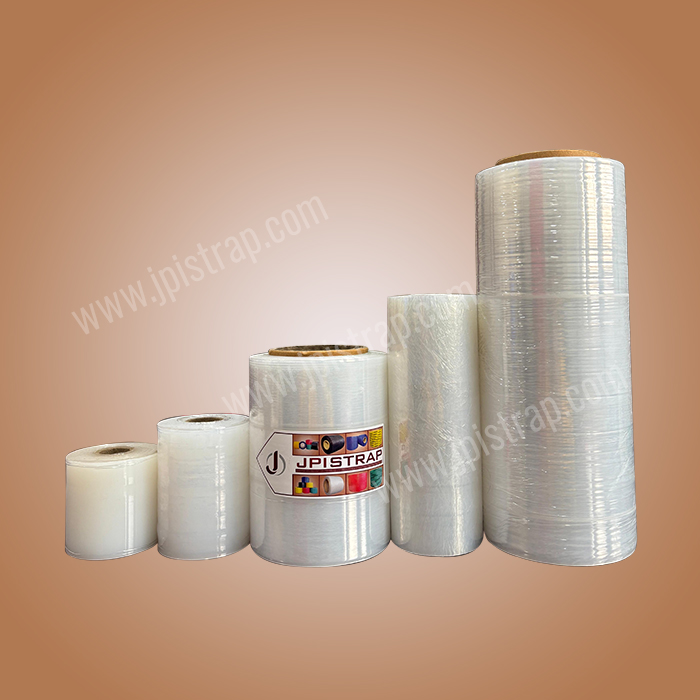

The blown stretch films as well as LLDPE cast stretch films are manufactured under utmost quality control, maintaining standards on the international level in most leading companies. The films come in many widths, thicknesses, and roll sizes, which are flexible to use manually or through machine use. Moreover, manufacturers in Gujarat tend to provide custom solutions to the unique needs of clients in terms of packaging peculiarities, such as branding, colors, UV protection, etc.

Due to the strategic position of Gujarat and its close connection with such ports as Mundra and Kandla, manufacturers are able to sell their products of stretch film to countries in Asia, Africa, Europe and the Middle East. Genuine competing prices, acceptable delivery and quality have made Gujarat a favoured sourcing item to buy stretch wrap.

When you need a professional and trusted stretch film producer in the state of Gujarat, consider a supplier with consistent quality of the product offered, customized services, and quality after-sales service. Looking to apply stretch film or industrial packaging or even commercially, the manufacturers in Gujarat offer reliable and strong stretch film that guarantees optimum stability of loads and protection of the products.

Specifications of Stretch Film

| Material |

|

| Dimensions – Width |

|

| Thickness (Microns/Gauge) |

|

| Roll Length |

|

| Stretchability |

|

| Core Size (Inner Diameter) |

|

| Clarity & Transparency |

|

| Types of Stretch Film |

|

| Load Retention & Holding Force |

|

| Temperature Resistance |

|

These specifications can vary depending on the manufacturer and the specific application requirements. It’s always a good idea to consult with the supplier or manufacturer for the exact specifications tailored to your needs.